When embarking on a construction or renovation project, selecting the right materials is crucial to ensure durability and efficiency. One essential component that often surfaces in building discussions is oriented strand board (OSB), a versatile engineered wood product widely used in construction and manufacturing. According to a recent report by the Engineered Wood Association, the demand for OSB has surged, with market growth projected to reach $14.2 billion by 2027. This growth underscores the importance of working with reliable OSB manufacturers who not only meet quality standards but also provide timely delivery and responsive customer service.

As noted by industry expert Dr. Jane Smith, a leading researcher in engineered wood products, “Selecting a trustworthy OSB manufacturer can significantly impact the success of your project, from structural integrity to overall cost-effectiveness.” With the market expanding, it becomes vital to navigate through various manufacturers, assessing factors such as production capabilities, environmental sustainability practices, and the types of OSB products offered. By carefully considering these key factors, professionals and homeowners alike can ensure they choose the right OSB manufacturer that aligns with the specific needs of their project, ultimately leading to enhanced performance and satisfaction.

Oriented Strand Board (OSB) is an engineered wood product that is widely utilized in construction. It is made from strands of wood that are oriented in specific directions and bonded together with adhesives under heat and pressure. This unique manufacturing process gives OSB its strength and durability, making it suitable for a variety of applications such as wall sheathing, roof decking, and subflooring. Because of its structural integrity, OSB is often preferred over traditional plywood in many projects.

One of the key benefits of OSB is its cost-effectiveness. It tends to be more affordable than plywood while still providing comparable performance in many scenarios. Additionally, OSB offers excellent moisture resistance, which is critical for buildings exposed to the elements. Its versatility allows for efficient use in both residential and commercial construction, providing a reliable solution for framing and finishing. As designers and builders continue to seek sustainable options, OSB’s use of smaller wood strands and byproducts from lumber mills contributes to reducing waste in the industry, further aligning with eco-friendly practices.

| Dimension | Thickness (inches) | Length (feet) | Width (feet) | Application | Environmental Rating |

|---|---|---|---|---|---|

| 4x8 | 0.5 | 8 | 4 | Subflooring | EPA Certified |

| 4x8 | 0.75 | 8 | 4 | Wall Sheathing | FSC Certified |

| 4x8 | 1.0 | 8 | 4 | Roof Decking | LEED Approved |

| 4x10 | 0.5 | 10 | 4 | Flooring Underlayment | Sustainable Sourcing |

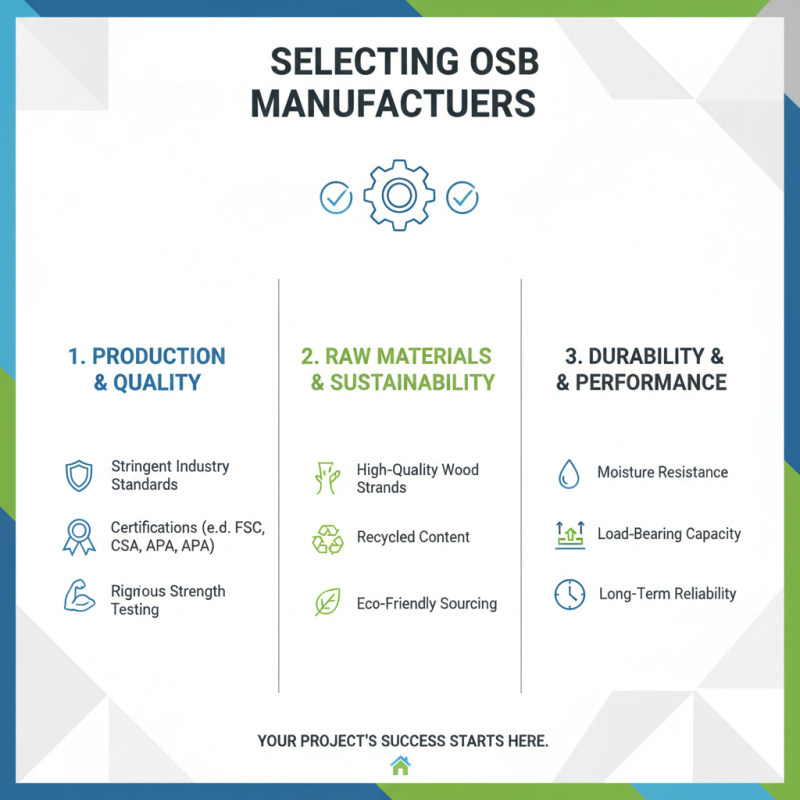

When selecting OSB (Oriented Strand Board) manufacturers for your next project, several key factors come into play that can significantly influence the success and durability of your construction. First and foremost, it's important to evaluate the manufacturer's production process and quality control measures. Look for manufacturers that adhere to stringent industry standards and certifications, which can ensure that the OSB panels are made with high-quality materials and have undergone rigorous testing for strength and durability. Understanding the raw materials used and their sustainability practices can provide further insight into the manufacturer’s commitment to quality and environmental responsibility.

Another crucial aspect to consider is the variety of products offered by the manufacturer. The needs of each project can vary widely, so having a range of OSB products that cater to different specifications—such as thickness, size, and moisture resistance—can make a significant difference. Additionally, consider the manufacturer’s customer service and support. Responsiveness to inquiries, assistance with product selection, and flexibility in meeting project timelines can greatly enhance your overall experience. By taking these factors into account, you can make a more informed choice, ensuring that you select an OSB manufacturer that aligns well with the specific demands of your project.

When selecting oriented strand board (OSB) for your next project, understanding the key differences among manufacturers can significantly influence your outcome. Various attributes, such as material quality, thickness options, and environmental impact certifications, set these manufacturers apart. A comparative analysis of leading OSB producers reveals that while many offer similar products, nuances in production processes and sustainability initiatives can make a substantial difference in performance and durability.

Tip: Always check for third-party certifications that confirm the environmental impact of the OSB you’re considering. Look for products that comply with GreenGuard or similar standards to ensure you're making a responsible choice for both your project and the environment.

Moreover, consider the feedback from industry professionals regarding the ease of installation and the performance of the OSB under various conditions. Some manufacturers may have a reputation for producing boards that withstand moisture or heat better than others. Evaluating these performance factors in different settings can help you make a well-informed decision that aligns with your project's specific needs.

Tip: Research online forums and trade publications for reviews and insights from builders who have firsthand experience with various OSB brands. Engaging with the community can provide valuable perspectives that might not be reflected in formal product descriptions.

When choosing oriented strand board (OSB) for your next project, understanding quality standards and certifications is crucial. OSB products are evaluated based on various performance metrics, including strength, durability, and moisture resistance. Certification from recognized organizations indicates that the product meets specific industry standards. For instance, adherence to norms such as ANSI (American National Standards Institute) and ASTM (American Society for Testing and Materials) ensures that the OSB has been rigorously tested and complies with safety and performance requirements.

Moreover, environmental certifications, such as those from the Forest Stewardship Council (FSC), can also play a vital role in your selection process. These certifications ensure that the raw materials used in the production of OSB come from sustainably managed forests. This not only contributes to environmental sustainability but also enhances the overall quality of the end product. Therefore, when assessing potential OSB manufacturers, it is essential to prioritize those who adhere to these quality standards and possess relevant certifications, as they reflect a commitment to reliability and sustainability in their manufacturing processes.

Sustainability is an increasingly vital consideration for builders and contractors when selecting oriented strand board (OSB) for their projects. The top OSB manufacturers are adopting innovative practices aimed at enhancing environmental stewardship. Research indicates that the global demand for sustainable building materials is expected to grow by over 20% in the next five years, prompting manufacturers to integrate more sustainable sourcing and production processes. Many leading OSB producers are now utilizing recycled wood fibers and responsible forest management to minimize their environmental impact, aligning their operations with the principles of the circular economy.

Tips: When evaluating OSB suppliers, consider their sustainability certifications and practices. Look for companies that have third-party certifications, such as Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI), which indicate a commitment to responsible forestry. Additionally, assess their transparency in disclosing sourcing methods and the ecological footprint of production.

Moreover, some manufacturers are investing in improved technologies to reduce waste and energy consumption during manufacturing. Reports suggest that advanced techniques can reduce waste by up to 30%, significantly lowering the carbon footprint of each board produced. By choosing OSB from manufacturers that prioritize sustainability, you not only benefit the environment but also position your project as a pioneer in responsible construction practices.

Tips: Don’t hesitate to ask suppliers about their energy use and waste management strategies. Understanding their environmental policies can help you make informed decisions that align with your sustainability goals.