Choosing the right structural plywood can be challenging. Mark Thompson, a renowned expert in the structural plywood industry, emphasizes the importance of careful selection. He once said, "The wrong choice can compromise your project’s integrity."

Understanding the key factors is crucial. Not all plywood is created equal. Variations in thickness, grade, and type can have a significant impact. Visualizing your project’s needs is vital before making a commitment. Consider the environment where the plywood will be used. Will it be exposed to moisture? Is it for indoor or outdoor use?

These questions guide your decision-making process. Flaws in selection can lead to unintended consequences. Selecting structural plywood is not just about cost. It’s about quality and suitability. Reflect on your choices to ensure long-term success for your projects.

Structural plywood is a versatile material widely used in construction. It is made from thin layers of wood veneer glued together, providing strength and durability. Understanding its types can help in choosing the right plywood for your project.

There are various types of structural plywood. For instance, marine plywood is resistant to moisture and often used in areas exposed to water. A recent report states that structural plywood markets are projected to grow by 3.5% annually, emphasizing its increasing popularity. Another common type is exterior plywood, which is treated to withstand outdoor elements. Proper classification is key; incorrect selection may cause structural failures over time.

Look for grades that ensure quality. Different standards, such as AS/NZS 2269, set benchmarks for strength. Not all plywood may meet these standards. Always check for certifications. A poorly selected plywood type can lead to issues like warping or delamination. Remember, taking shortcuts could compromise the integrity of your project. Invest time in understanding the types available and consult experts if needed.

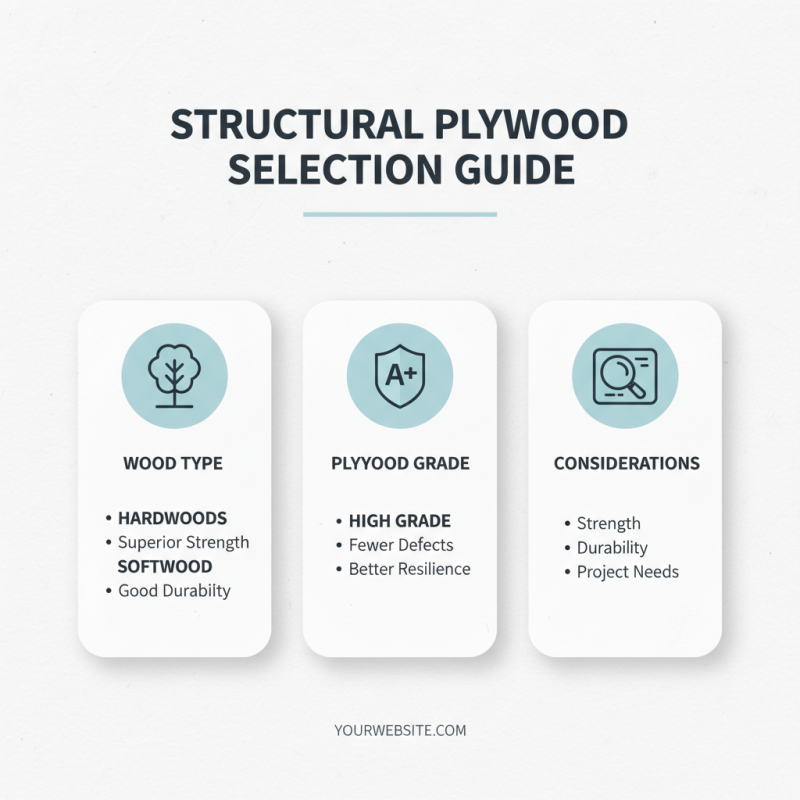

When choosing structural plywood, there are key factors to consider. The type of wood used is crucial. Different woods offer varying strength and durability. For instance, hardwoods generally provide better structural integrity than softwoods. Look for plywood with a high plywood grade. Higher grades indicate fewer defects and better resilience against wear.

Thickness is another important aspect. Standard structural plywood ranges from 3/8 inch to 1 inch thick. Thicker sheets tend to be stronger and more stable, making them ideal for heavy loads. However, you might find thinner options useful for lighter applications. Always assess your specific needs. Reflect on whether you can compromise on thickness for cost savings or if strength is non-negotiable.

Moisture resistance also plays a vital role. Plywood can be exposed to varied weather conditions. Choosing a type with waterproof glue or a water-resistant veneer can prolong its lifespan. Be cautious, as moisture can lead to warping and decay. Lastly, consider sourcing quality materials. Poor-quality plywood may save money upfront, but it can cause costly repairs down the line. Balancing cost, durability, and intended use is essential for making the right choice.

When selecting structural plywood, evaluating its strength and load-bearing capacity is essential. The weight it needs to support directly influences your choice. Check the specific grading of the plywood. Higher grades usually indicate better strength and fewer defects.

Consider the thickness of the plywood. Thicker sheets generally provide greater strength. However, they can also be heavier and more difficult to handle. Balance your need for strength with practicality. Test the plywood by applying pressure to see how it withstands weight.

Understand the environmental conditions as well. Humidity can weaken plywood. Make sure it suits your project's location. Look at the edges of the plywood. They should be smooth and free from voids. Imperfections can impact the overall strength.

Take your time and reflect on these tips. A thoughtful approach helps ensure you make the right choice.

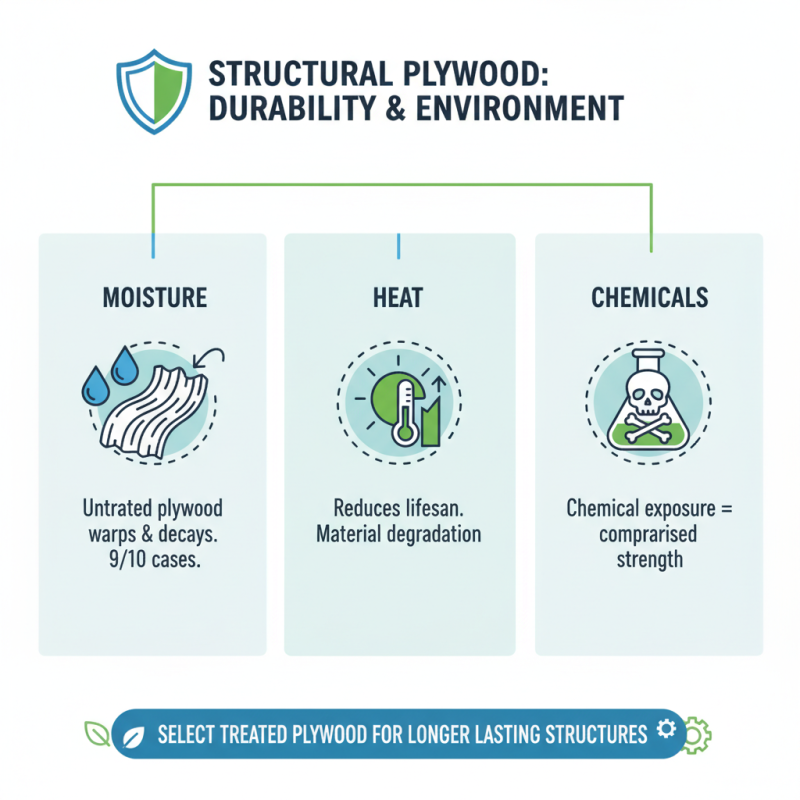

When selecting structural plywood, assessing environmental resistance and durability is crucial. Plywood’s longevity is significantly influenced by its exposure to moisture, heat, and chemicals. Research indicates that untreated plywood can absorb moisture, leading to warping or decay in nine out of ten cases. This degradation can drastically reduce the material's lifespan.

Certain types of plywood are designed to withstand harsh conditions. For example, marine-grade plywood contains additional layers and waterproof adhesives. These features enhance its resistance to humidity and water damage. According to industry studies, properly treated plywood can last up to 50% longer than untreated options when exposed to wet environments. But, not all consumers recognize the differences in treatment processes. Many plywood buyers overlook the importance of checking for certifications that ensure moisture resistance.

Durability is not solely about moisture. UV exposure can weaken materials too. Plywood left unprotected in the sun may deteriorate within a few months. A critical gap in awareness exists regarding the effects of UV rays on structural integrity. Homeowners often regret not using UV-resistant finishes on their plywood. It’s essential to evaluate product specifications and maintenance requirements before making a choice. Making informed decisions will ensure the plywood performs well under various environmental conditions.

When selecting structural plywood, understanding certification standards is crucial. Certifications often indicate quality and safety. Look for labels that confirm compliance with industry standards. This is a good starting point. Certifications such as the Engineered Wood Association standards show that the product has gone through rigorous testing.

Not all plywood types are created equal. Some may look good but lack durability. A quality certification should indicate strength, moisture resistance, and adhesion properties. If a plywood sheet doesn’t have any certification, it raises concerns. This can lead to unexpected issues. Sometimes, cheaper options seem appealing, but they often compromise safety.

Pay attention to the details on certification labels. They provide insights on the manufacturing process and materials. It’s easy to overlook these aspects in pursuit of lower costs. However, a certified product is an investment in durability and safety. Choose wisely to avoid potential setbacks in your projects. It’s worth taking the time to ensure that your plywood meets the necessary standards.