In recent years, the demand for Commercial Plywood has surged significantly, driven by the booming construction and furniture industries. According to a recent report by Market Research Future, the commercial plywood market is projected to reach USD 16.92 billion by 2027, growing at a CAGR of 6.48% from 2020 to 2027. This growth underscores the necessity for businesses to make informed decisions when selecting plywood for their projects.

With various types and grades available, understanding the specific properties and applications of commercial plywood is vital for ensuring both quality and durability.

Whether you're in the construction sector or involved in manufacturing, choosing the right type of commercial plywood can enhance product longevity and performance. In this ultimate guide, we'll explore key considerations, types of commercial plywood, and expert tips to help you make the best choice for your business needs.

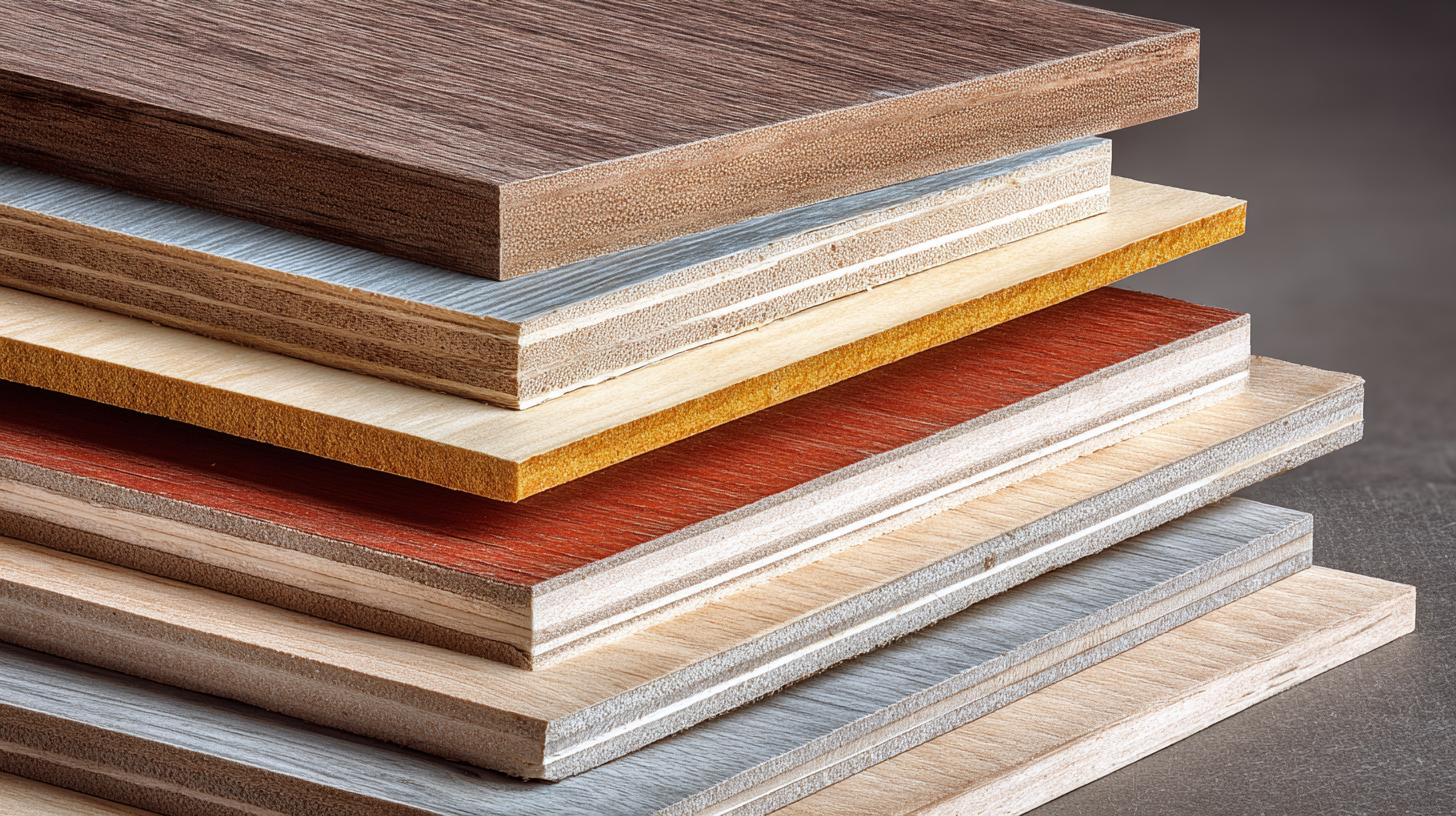

When selecting commercial plywood for your business needs, it's crucial to understand the various types available and their specific applications. Plywood can generally be categorized into two main types: softwood and hardwood. Softwood plywood, made from trees like pine and fir, is often used in construction and industrial applications due to its lightweight and cost-effective nature. In contrast, hardwood plywood, made from hardwood species, boasts superior strength and durability, making it ideal for furniture manufacturing and high-end woodworking projects.

The global plywood market has shown significant growth potential, with projections indicating that it could reach over $104 billion by 2033. This growth is driven by increasing demands in the construction sector and innovations in manufacturing processes. Different grades of plywood are also available, which further impact their application. For instance, interior-grade plywood is suitable for indoor furniture and cabinetry, while exterior-grade plywood is designed for outdoor use, ensuring resistance to moisture and other environmental factors. Understanding these distinctions will help you make informed decisions that align with your project requirements and budget.

When it comes to selecting the right commercial plywood for your project, several key factors play a significant role in ensuring you make the best choice. One of the primary considerations is the type of plywood you need based on its intended use. For instance, furniture-grade plywood typically has a smooth finish and fewer defects, making it ideal for visible surfaces, while structural plywood is better suited for heavy-duty applications requiring strength and durability.

Another critical factor is the plywood's grade and thickness. Higher-grade plywood offers better surface quality and fewer imperfections, while thickness impacts the plywood's strength and load-bearing capacity. It's essential to select a thickness that aligns with your project requirements to avoid potential failures or damages down the line.

**Tip:** Always check for the plywood's certification, such as APA (The Engineered Wood Association) standards, to ensure you're getting a quality product.

**Tip:** Don't forget to factor in environmental conditions; plywood meant for outdoor usage should be treated for moisture resistance, whereas interior plywood can prioritize aesthetics over durability.

By paying careful attention to these factors, you can confidently choose the plywood that meets your business needs and project specifications.

When it comes to selecting commercial plywood, the balance between cost and quality is crucial for any business. The global plywood market is expected to reach approximately $85 billion by 2027, growing at a CAGR of over 5% from 2020 to 2027, according to a recent market research report. This trend emphasizes the importance of choosing high-quality materials that not only meet budget constraints but also ensure durability and performance.

One critical tip for making the right selection is to prioritize your project's specific needs over the lowest price. For instance, while softwood plywood might be less expensive, it may not provide the same structural integrity needed for heavy-duty applications. Opt for hardwood plywood when strength and resilience are demanded, as it often justifies the higher upfront investment through longevity and reduced maintenance costs.

Another important consideration is sourcing from reputable suppliers. According to the U.S. Forest Service, approximately 50% of plywood produced is of low quality due to poor manufacturing practices. By choosing trustworthy suppliers who adhere to industry standards, you can avoid the pitfalls of subpar materials that can affect both your projects and bottom line. Investing time in supplier research can lead to significant long-term savings and enhanced product performance.

When sourcing high-quality commercial plywood for your business, it is essential to understand the current market dynamics and innovations in the plywood industry. Recent trends indicate a growing focus on sustainability and efficiency in manufacturing practices, which can significantly influence your decisions as a buyer. Staying informed about these trends helps ensure that you select suppliers who align with your operational needs and values.

One of the key tips for sourcing plywood is to evaluate suppliers based on their manufacturing processes. Look for companies that prioritize sustainable practices and innovative solutions, as these attributes often correlate with higher product quality. In regions like Canberra, there are several reputable suppliers emerging who meet these standards. Customer reviews and industry ratings can also guide you in assessing potential suppliers’ reputations.

Additionally, consider the specific requirements of your projects, such as the desired thickness, finish, and durability of the plywood. This will help you communicate effectively with suppliers and ensure that you receive the best materials for your applications. Engaging with local suppliers not only supports your community but can also provide more responsive service and better lead times for your orders.

When it comes to maximizing the lifespan of commercial plywood products, proper maintenance and care are essential. First and foremost, consider the environment where the plywood is used. High humidity and direct exposure to moisture can lead to warping and rot, so it’s crucial to store plywood in a dry area. If the product is used in spaces prone to dampness, applying a waterproof sealant can provide an extra layer of protection, ensuring longevity and structural integrity.

Additionally, regular cleaning is vital to prevent the buildup of dirt and grime that can affect both aesthetics and functionality. Use a mild detergent and soft cloth to wipe down surfaces. Avoid harsh chemicals that might damage the finish. Furthermore, inspect the plywood periodically for signs of wear, such as scratches or cracks. Promptly addressing these issues, such as sanding down rough edges and reapplying finish, can greatly extend the life of your plywood, making it a worthwhile investment for your business needs.