Building plywood is increasingly recognized as a top choice for construction projects, thanks to its remarkable strength, versatility, and cost-effectiveness. As the construction industry continues to evolve, the demand for high-quality materials that can withstand the rigors of building applications has skyrocketed. According to industry expert Dr. Emily Carter, a leading authority in structural engineering, "Building plywood offers unparalleled benefits for both small-scale renovations and large commercial constructions, making it an indispensable material for today's builders."

The significance of building plywood lies not only in its durability but also in its sustainability. As eco-conscious practices gain traction in the construction field, builders and architects are turning to building plywood for its renewable features. Unlike traditional lumber, which can lead to deforestation, building plywood can be sourced from sustainable forests, providing an environmentally friendly alternative that does not compromise on quality. Dr. Carter emphasizes, "When you choose building plywood, you're not just choosing a material; you're committing to a sustainable future in construction."

In conclusion, the advantages of building plywood extend far beyond mere functionality. It stands as a robust solution that integrates both structural integrity and ecological responsibility, making it the best choice for any construction project. As we delve deeper into the reasons why building plywood should be at the forefront of your material choices, you'll discover how it can enhance not only the efficiency of your project but also contribute positively to the environment.

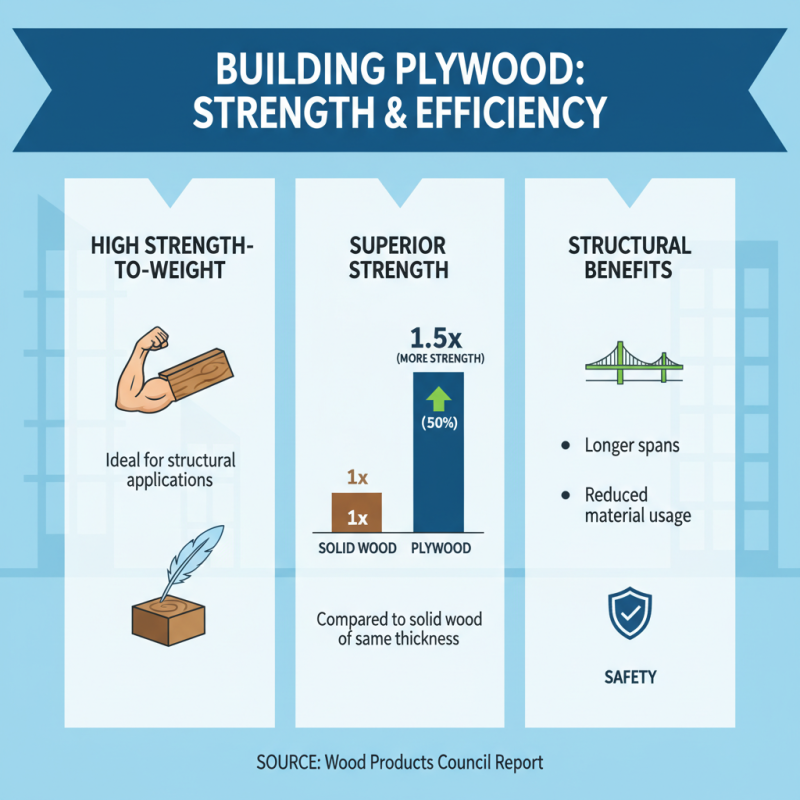

Building plywood has emerged as a preferred material in modern construction practices, thanks to its versatility, strength, and cost-effectiveness. According to the Wood Products Council, building plywood is not only lightweight but also boasts a high strength-to-weight ratio, making it ideal for a wide variety of applications, from structural support to interior finishes. This characteristic allows builders to reduce the overall weight of structures without compromising safety, which can save on foundation costs and improve project timelines.

Additionally, building plywood is known for its sustainability. The APA – The Engineered Wood Association reports that plywood production utilizes fast-growing timber species, promoting faster forest replenishment. This aligns with the growing trend in the construction industry towards more environmentally friendly practices. Moreover, building plywood is easily recyclable and can be repurposed, reducing waste in landfills and contributing to more sustainable construction cycles.

Tips: When selecting plywood for a project, always consider the grade and thickness to ensure it meets your structural requirements. Also, check for certifications that indicate sustainability and quality, as these can further enhance the durability of your project. Finally, storing plywood properly to avoid warping or water damage is essential to maintain its integrity throughout the construction process.

Building plywood has gained prominence in the construction industry due to its remarkable properties that significantly enhance structural integrity. One key aspect of building plywood is its high strength-to-weight ratio, making it an ideal choice for various structural applications. According to a recent report by the Wood Products Council, plywood can achieve up to 50% more strength compared to solid wood of the same thickness, which allows for longer spans and reduced material usage without compromising safety.

Another crucial property of building plywood is its dimensional stability. Unlike traditional solid wood, plywood is engineered to resist warping, twisting, and splitting, ensuring that structures remain sound under various environmental conditions. The American Plywood Association points out that when properly treated, plywood can withstand moisture levels that would typically compromise solid wood products, thus extending the lifespan of the construction. Additionally, plywood's layer-by-layer construction imparts enhanced resistance to fire, a quality vital for maintaining safety in residential and commercial buildings.

Finally, the versatility of building plywood cannot be overstated. Its ability to be manufactured in various thicknesses and grades allows it to be utilized in everything from flooring to roofing systems. Furthermore, the recent trends highlighted in the Global Wood Market Report indicate a growing preference for sustainable materials like plywood, with more than 60% of builders asserting that they plan to incorporate eco-friendly materials in their upcoming projects, thereby promoting environmental sustainability alongside structural integrity.

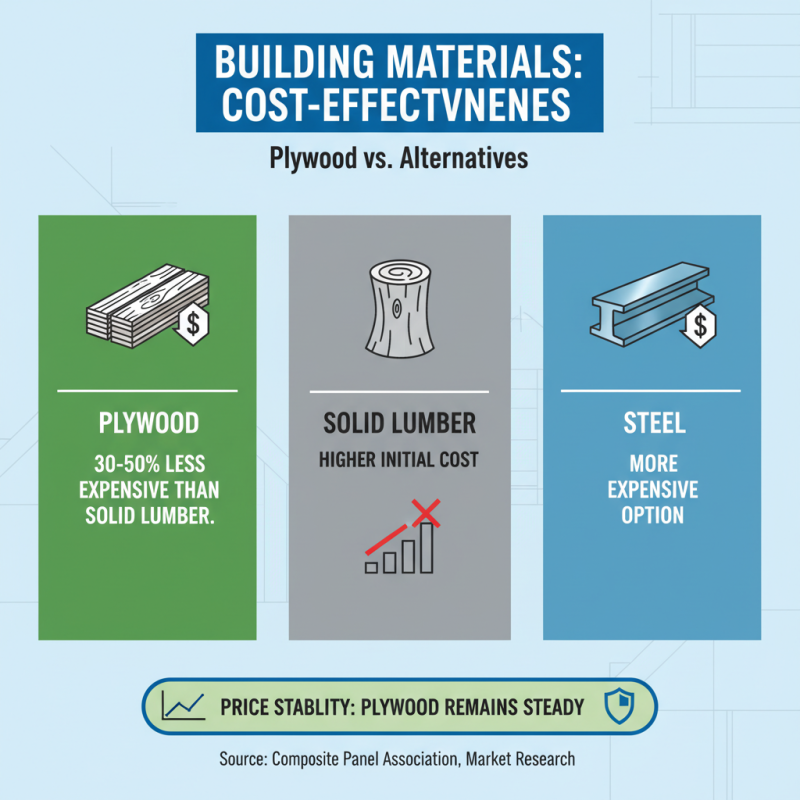

When evaluating materials for construction projects, cost-effectiveness is often a crucial factor. According to data from the Composite Panel Association, building plywood can be significantly more economical than alternative materials like solid wood or steel. For instance, the average cost of plywood is typically 30-50% less than that of solid lumber, while offering comparable structural integrity. Additionally, with recent market research indicating that the price of plywood has remained stable even amidst fluctuating wood prices, it presents a reliable option for budget-conscious builders.

Furthermore, building plywood offers efficiencies in both installation and longevity. The time saved during construction can lead to lowered labor costs, which are estimated to account for up to 30% of the total project expenditure. A report by the National Wood Flooring Association suggests that when considering lifecycle costs, plywood's durability leads to fewer repairs and replacements over time compared to other materials, reinforcing its cost-effectiveness. Overall, the combination of lower upfront costs and long-term value makes building plywood a leading choice for construction projects focusing on budget efficiency.

Building plywood is increasingly recognized as a top choice for construction projects due to its inherent sustainability features. As a renewable resource, plywood is produced from trees that are often managed in a sustainable manner, ensuring that forests are preserved for future generations. This wood material undergoes minimal processing compared to other building materials, which reduces its overall carbon footprint. Moreover, the utilization of fast-growing species for plywood production accelerates the replenishment cycle, further aligning with eco-friendly construction practices.

In addition to its sustainable sourcing, building plywood also exhibits excellent durability and versatility, making it suitable for a wide range of applications in eco-friendly projects. Its lightweight nature allows for efficient transportation and easier handling on-site, which can minimize fuel consumption during logistics. Plywood can be used in structural applications, as well as interior finishes, demonstrating its adaptability. Furthermore, when sourced and treated responsibly, it can contribute to very low levels of harmful emissions, ensuring healthier indoor environments. By prioritizing building plywood, construction projects not only benefit from a reliable material but also support sustainable practices that benefit the planet.

Recent industry statistics reveal a significant upward trend in the usage of plywood for construction projects. According to recent data, plywood accounts for over 40% of the total structural wood used in construction, reflecting its popularity among builders and contractors. This surge in usage can be attributed to plywood's versatility, strength-to-weight ratio, and cost-effectiveness. The rise in residential and commercial construction projects has bolstered the demand for building plywood, as it serves as a reliable material for various applications, including flooring, walls, and roofs.

Moreover, a study indicates that the demand for environmentally sustainable building materials is influencing plywood usage. As construction companies increasingly prioritize sustainable practices, plywood emerges as a favorable option due to its renewable nature and potential for recycling. Furthermore, over 60% of industry professionals surveyed stated that they prefer plywood for framing and sheathing because it provides excellent durability without compromising structural integrity. With these statistics in mind, it is clear that plywood is not just a material of choice but an integral component driving the future of construction.