When embarking on a woodworking project, the choice of materials can significantly impact the final result, making it essential to select the right kind of plywood. Among the various options available, Premium Plywood stands out due to its superior quality and performance. According to a recent market analysis by Grand View Research, the global plywood market is projected to reach USD 90 billion by 2025, with a notable segment of this growth driven by the demand for high-grade materials in construction and furniture manufacturing.

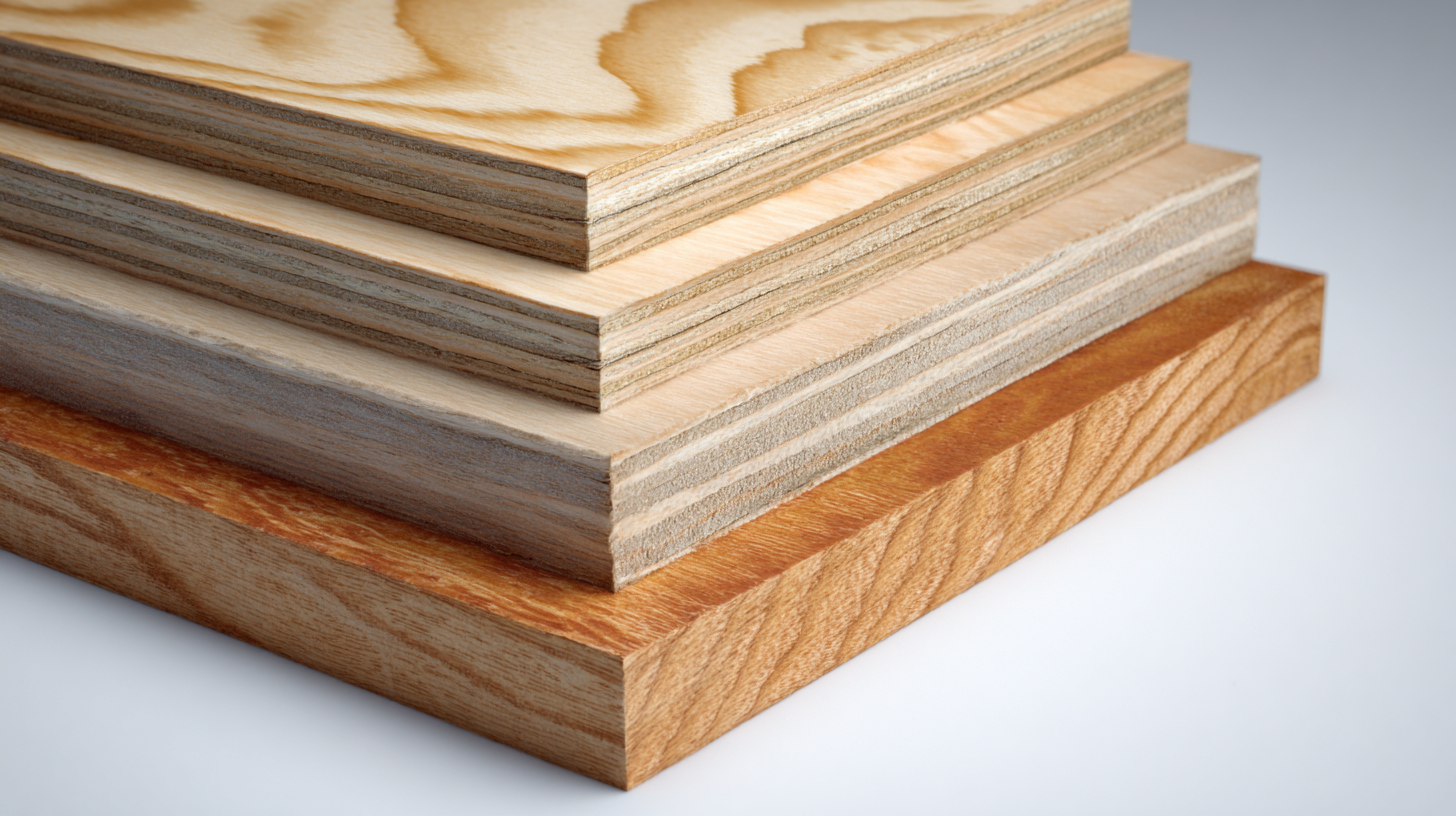

Premium Plywood not only offers enhanced durability and visual appeal but also exhibits superior resistance to warping and moisture, making it ideal for a range of applications. Understanding how to identify the best Premium Plywood for your specific needs is crucial for achieving both aesthetic and structural success in your projects.

In 2025, the landscape of premium plywood offers a variety of options to suit different project needs. With the global plywood market projected to grow from USD 62.67 billion in 2025 to an astounding USD 104.53 billion by 2033, it’s essential to understand the types available. The rise in market size reflects innovations in manufacturing processes, leading to improved quality and sustainability in plywood products. This enhancement is not just about aesthetics; it significantly impacts durability and versatility, crucial for both builders and DIY enthusiasts.

Different types of premium plywood cater to diverse applications, ranging from high-grade hardwood for furniture to specialized marine-grade plywood, known for its resistance to moisture. Suppliers in Canberra are well-equipped to provide quality choices that ensure durability and strength for any project. As consumer demands evolve, the availability of eco-friendly options further encourages sustainable building practices in the plywood industry, promoting a future where innovative materials meet the environmental standards expected by today's consumers.

When selecting premium plywood for your project, several key factors need careful consideration to ensure optimal performance and durability. One critical aspect is the wood species, as different types exhibit varying strength and aesthetic properties. For instance, marine-grade plywood, often made from high-quality Douglas fir or okoume, is known for its exceptional resistance to moisture and delamination, making it ideal for boatbuilding and exterior applications. According to the American Plywood Association, using the right species can enhance the longevity of your product by up to 30% in harsh environments.

Another vital factor is the plywood grade. Premium plywood typically features fewer defects such as knots and voids, which can compromise structural integrity. Grades like A or B, as classified by the APA, offer a smoother finish and higher durability. Data from the Wood Products Council indicates that projects utilizing higher-grade plywood not only improve aesthetic appeal but also result in significant cost savings over time due to reduced maintenance needs. Additionally, consider the adhesive used in the plywood’s construction; exterior-grade adhesives provide enhanced moisture resistance and contribute to the overall strength of the panels, particularly in high-humidity areas.

| Factor | Description | Recommended Value |

|---|---|---|

| Wood Type | The species of wood used in the core and veneers, impacting strength and appearance. | Birch or Oak |

| Thickness | The overall thickness of the plywood, affecting durability and applications. | 1/2 inch or 3/4 inch |

| Grade | Quality grading indicating the appearance and defect allowance of the veneer. | AA or A |

| Glue Type | Type of adhesive used in plywood construction, impacting moisture resistance. | Exterior glue (like WBP) |

| Environmental Certification | Certifications that indicate sustainable sourcing practices. | FSC Certified |

| Finish | Surface treatment affecting aesthetics and durability. | Smooth sanded or veneered |

As the demand for sustainable and premium materials rises, the plywood market is projected to reach an impressive USD 60.31 billion by 2030. This growth is driven by emerging trends in plywood manufacturing that emphasize both sustainability and quality. The shift towards eco-friendly practices is evident as manufacturers embrace innovative techniques that reduce waste and enhance the longevity of the product. The surge in interest for engineered wood products further supports this trend, as consumers seek alternatives that combine aesthetics with durability.

One notable development is the introduction of lightweight plywood applications, like electric bikes, which highlight the versatility of plywood in modern designs. Such innovations not only cater to a growing audience focused on sustainability but also showcase traditional woodworking techniques, attracting a diverse range of customers. In parallel, the global veneer sheets market is expected to expand significantly, fueled by the rising demand for decorative and sustainable wood finishes. This interconnection between plywood and veneer products is shaping the future of the industry, promoting environmentally responsible choices while meeting the needs of contemporary projects.

When selecting premium plywood for your projects, understanding quality and durability is crucial. According to industry standards, premium plywood is often graded based on the type of wood used, the number of layers, and the adhesive quality. A common benchmark is the use of exterior-grade adhesive which ensures that the plywood can withstand moisture and temperature changes, making it ideal for both indoor and outdoor applications. Expert evaluations indicate that BB/BB grade plywood, with a smooth finish on both sides, is suitable for projects requiring aesthetic appeal, ranging from furniture to cabinetry.

Moreover, durability tests reveal that thickness plays a significant role in the longevity of plywood. Plywood typically comes in various thicknesses, with ¾ inch being a popular choice for flooring and structural applications. According to a recent durability study, plywood with a thicker veneer layer exhibits better resistance to dents and scratches, ensuring that your finished projects maintain their appearance over time. When assessing plywood options, look for certifications such as the APA (American Plywood Association) stamp, which signifies that the plywood has met rigorous performance standards.

When selecting plywood for your projects, avoiding common mistakes can save you time, money, and frustration. One major pitfall is underestimating the importance of the plywood's grade. Many assume that higher grades are solely more expensive without considering their specific applications. For instance, A-grade plywood is smooth and free of defects, making it ideal for visible surfaces in furniture, while lower grades may be suitable for hidden structural elements. Understanding these distinctions ensures you choose the right plywood for your needs.

Another mistake is neglecting moisture resistance, especially if your project will be exposed to the elements or in high-humidity areas. Not all plywood is treated for moisture resistance, and using the wrong type can lead to warping or decay over time. Always check the manufacturer's specifications and consider selecting marine-grade or exterior-grade plywood for projects that will endure moisture.

By remaining mindful of these considerations, you can make an informed choice that enhances the longevity and appearance of your work.