Choosing the right concrete plywood for your project can be challenging. It is crucial to understand the various options available. John Smith, a leading expert in the concrete plywood industry, once said, "Selecting the right material makes all the difference in a project's success."

Concrete plywood serves various purposes. It provides the necessary strength and durability for construction projects. However, not all concrete plywood is created equal. Understanding your specific needs can lead to better choices. Factors include the type of project and the environmental conditions.

Selecting the wrong product can lead to costly mistakes. Many overlook the impact of weather on plywood performance. It's vital to assess how plywood can withstand moisture and pressure. With a little foresight and expert advice, you’ll navigate this intricate field more effectively. Remember, not all choices are straightforward, and reflection on past decisions may offer valuable insights.

When choosing concrete plywood, it’s vital to understand the different types available in the market. There are several varieties, each designed for specific applications. For example, structural plywood is commonly used for floors and walls. It’s strong and built to withstand heavy loads. On the other hand, marine-grade plywood is great for areas that are exposed to moisture. This type is treated to resist rot and deterioration, making it ideal for outdoor projects.

Tips for choosing the right type of concrete plywood include assessing your project needs. Consider the environmental conditions it will face. Will it be exposed to water or heavy wear? If so, select the appropriate grade. Additionally, be mindful of thickness. Thicker plywood offers better durability, but it can be heavier and more challenging to handle. Test different types before finalizing your choice.

Visualizing where and how the plywood will be used can help. If you need a lightweight option, thin plywood may suffice. However, remember that thinner boards could compromise the structure's integrity over time. A balance between weight and strength is essential. Take time to reflect on your project's needs before making a decision.

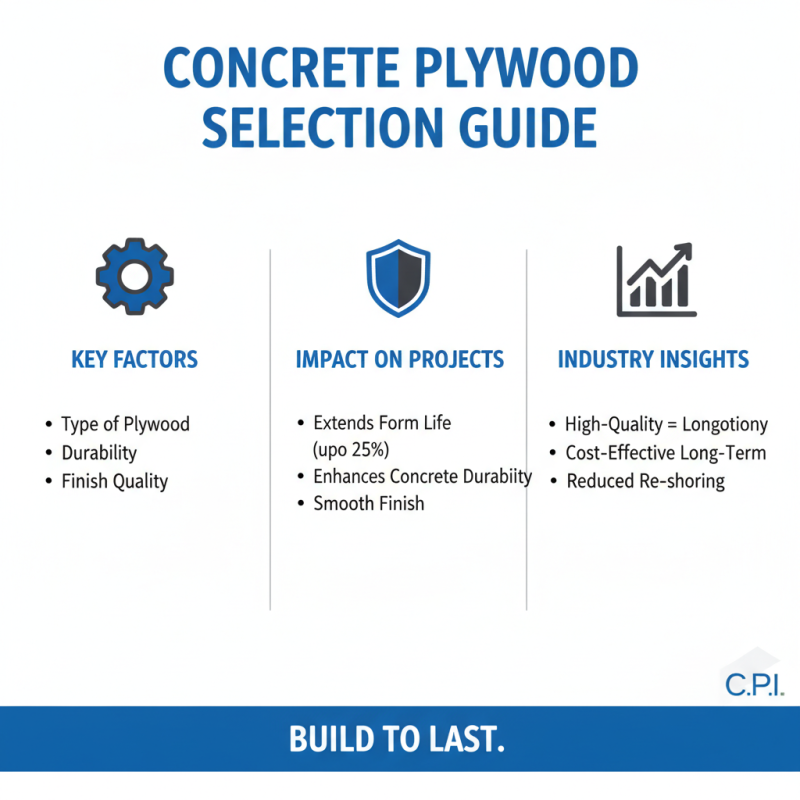

When selecting concrete plywood for your project, several key factors come into play. The type of plywood you choose can significantly impact the durability and finish of your work. Industry studies show that using high-quality concrete plywood can extend the life of your concrete forms by up to 25%. This is crucial for ensuring longevity in construction.

Another important aspect is the thickness of the plywood. Thicker plywood provides better support and reduces warping. Many professionals recommend a minimum thickness of 15mm for optimal performance. Be cautious; thinner sheets may seem cost-effective, but they can lead to issues during the pouring process.

Here are some tips for choosing the right concrete plywood:

1. Look for plywood with a high veneer grade. This ensures fewer defects.

2. Check for moisture resistance. It’s an essential feature for long-lasting performance.

3. Evaluate the potential for reuse. Quality plywood can save costs in the long run.

Pay attention to these details. The wrong choice could lead to unnecessary headaches down the line. Always consider how environmental conditions may affect the plywood, as it can influence both the application and the final results.

When considering concrete plywood, durability and strength are critical factors. A study by the Concrete Industry Board highlights that plywood with higher density typically offers better strength. For example, plywood with a density above 40 lbs per cubic foot often withstands heavy loads more effectively. This makes it suitable for constructions like flooring and wall systems.

Strength specifications also matter. The American Plywood Association states that structural plywood must meet specific shear and bending strength requirements. For projects exposed to moisture, like in humid climates, durability becomes even more crucial. Choosing plywood with a lower water absorption rate can significantly extend its lifespan. Some plywood types may not meet these criteria consistently, and it is essential to verify certifications and testing data to ensure reliability.

Additionally, while aiming for the best options, it's easy to overlook budget constraints. Sometimes, cheaper plywood may seem adequate, but it often leads to quicker deterioration, costing more in the long run. A careful balance between cost and quality is necessary. Evaluating the intended use and environmental conditions will help avoid pitfalls related to improper material selection.

When selecting concrete plywood, cost and quality are crucial factors to consider. Quality plywood can ensure better durability and performance. However, higher quality often comes with a steeper price tag. This can make budgeting for your project challenging. You may find that cheaper options are misleading. They might seem budget-friendly but could lead to costly repairs later.

Think about the project's requirements. Will the plywood be exposed to extreme weather? If so, investing in high-quality plywood is wise. Lower-quality options may not stand the test of time, costing you more in the long run. Keep an eye on certifications and specifications. Sometimes these details reveal the true value of the product.

Remember, appearance matters too. Aesthetics can be essential for visible projects. Low-cost plywood may look good initially. However, it can deteriorate quickly and require replacement. Reflect on what you need versus what you want. A thoughtful choice today can save time and money in future endeavors.

When installing concrete plywood, proper preparation is essential. The surface must be clean and free of debris. Industry reports indicate that a 1% deficiency in preparation can lead to a 10% increase in moisture levels, causing potential damage to the plywood. Utilize a moisture meter to check the surface. This small step can save costly repairs.

During installation, use the right fasteners. A study found that improper fasteners can decrease the longevity of plywood by up to 30%. Keep sections tight to avoid gaps. Gaps can trap moisture, leading to degradation. Ensure all edges are sealed with high-quality sealant to create a barrier against water damage.

Maintenance plays a key role in the lifespan of concrete plywood. Regular inspection can catch issues early. Look for signs of wear or moisture damage. A report from industry experts suggests that routine applying of waterproof coatings every few years can extend the life of plywood significantly. It’s better to address minor issues before they escalate. This proactive approach can lead to a 15% reduction in overall repair costs.

| Dimension | Material Type | Thickness | Application | Maintenance Tips |

|---|---|---|---|---|

| 4' x 8' | Bamboo | 3/4" | Formwork | Clean with water and avoid prolonged exposure to moisture. |

| 4' x 10' | Plywood | 1/2" | Shuttering | Apply a protective sealant to extend lifespan. |

| 5' x 10' | Fiber Cement | 5/8" | Concrete Forming | Regularly check for wear and replace damaged sections. |

| 4' x 8' | OSB | 3/8" | Underlayment | Store in a dry area to prevent warping. |