In the ever-evolving landscape of construction materials, Concrete Plywood has emerged as a game-changer, offering a blend of durability and versatility that is hard to match. According to industry expert Dr. Emily Carter, a leading researcher in sustainable building materials, "Concrete Plywood not only enhances structural integrity but also provides a sustainable solution that meets the demands of modern construction." As construction projects increasingly prioritize eco-friendliness alongside strength, Concrete Plywood stands out by combining the benefits of traditional plywood with the enhanced performance characteristics of concrete.

The utilization of Concrete Plywood is gaining traction among architects and builders alike, thanks to its unique properties that cater to various construction needs. Its ability to withstand harsh weather conditions and heavy loads makes it an exceptional choice for both residential and commercial applications. With its lightweight nature and easy-to-handle panels, Concrete Plywood simplifies the construction process while ensuring high-quality results. As the construction industry continues to seek innovative materials that align with sustainability goals, Concrete Plywood represents a significant advancement that can redefine project outcomes.

Concrete plywood, also known as formwork plywood, is a specialized composite material designed to meet the demands of various construction projects. Its primary composition includes a layer of plywood that is treated with a concrete-grade resin, providing enhanced durability and moisture resistance. This makes it ideal for applications such as foundations, walls, and slabs, where exposure to water and heavy loads is a factor. The combination of high-quality veneers and protective treatments ensures that concrete plywood can withstand the harsh conditions often encountered on construction sites.

Tips for using concrete plywood effectively include ensuring proper storage and handling to prevent warping or damage before use. It's essential to keep the sheets elevated off the ground and covered to protect them from moisture and direct sunlight. Additionally, when cutting or shaping the concrete plywood, using the right tools is crucial to achieve clean edges, which will help in achieving a seamless fit during installation. Lastly, always follow the manufacturer's guidelines for mixing and pouring concrete to ensure optimal results when using concrete plywood as a formwork solution.

| Benefit | Description | Application |

|---|---|---|

| Durability | Resistant to moisture, rot, and insects, ensuring a long lifespan. | Formwork, scaffolding, and temporary structures. |

| Cost-Effectiveness | Lower overall project costs due to its reusability and longevity. | Construction of foundations and walls. |

| Versatility | Suitable for various types of construction projects across industries. | Residential, commercial, and industrial builds. |

| Eco-Friendly | Made from sustainable materials, reducing environmental impact. | Green building projects and LEED certifications. |

| Strength | High structural integrity ensures stability and load-bearing capacity. | Load-bearing walls and flooring systems. |

Concrete plywood, often regarded for its durability and versatility, offers a spectrum of advantages that make it a preferred choice in construction applications. One of the key benefits is its superior strength and load-bearing capacity. Unlike traditional plywood, concrete plywood is designed to withstand heavy loads and resist deformation over time. This makes it an excellent material for formwork, providing the structural integrity necessary during the concrete pouring process. Its ability to hold up under stress ensures that projects remain on track without the need for frequent replacements or repairs.

Another significant advantage is its resistance to moisture and environmental damage. Concrete plywood is engineered to withstand exposure to water and humidity, reducing the risk of warping or rotting that is common with standard wood products. This property is particularly valuable in construction environments where weather conditions can be unpredictable. Additionally, its fire-resistant capabilities enhance safety on the job site, making it an ideal choice for applications where fire hazards are a concern. With such robust characteristics, concrete plywood not only improves the longevity of construction projects but also contributes to safer and more efficient building processes.

Concrete plywood offers remarkable durability and longevity, making it an ideal choice for various construction projects. Unlike traditional plywood, which tends to be susceptible to water damage, mold, and warping, concrete plywood is engineered to withstand harsh environmental conditions. Its compositional structure includes a combination of cement and wood fibers, resulting in a robust material that resists rot and deterioration. This unique formulation not only extends its lifespan but also reduces the need for frequent replacement, ultimately lowering maintenance costs over time.

Another significant advantage of concrete plywood is its performance under heavy loads and high-impact scenarios. When compared to traditional options, concrete plywood displays superior strength and stability, making it suitable for applications that require a solid foundation, such as scaffolding, formwork, and flooring. Its ability to endure intense pressure and stress means that it can be relied upon to support heavy materials without compromising structural integrity. Consequently, opting for concrete plywood not only ensures a more resilient framework but also contributes to the overall safety of construction projects, further underscoring its superiority over conventional plywood solutions.

Concrete plywood has emerged as a popular choice among builders due to its cost-effectiveness and durability. One of the primary economic benefits of using concrete plywood for construction projects is its long lifespan compared to traditional materials. This resilient material can withstand harsh environmental conditions and heavy usage, reducing the need for frequent replacements and repairs. As a result, construction teams can save significantly on maintenance costs over the lifespan of the project.

Additionally, concrete plywood's installation process can lead to financial savings. It is often easier and quicker to install than other building materials, which can decrease labor costs. Reduced time on site means that projects can be completed more efficiently, allowing contractors to take on more work and enhance their profit margins. Moreover, the versatility of concrete plywood allows for various applications, from flooring to wall sheathing, which maximizes its utility and minimizes material waste. By investing in concrete plywood, builders can effectively manage their budgets while ensuring high-quality, durable construction.

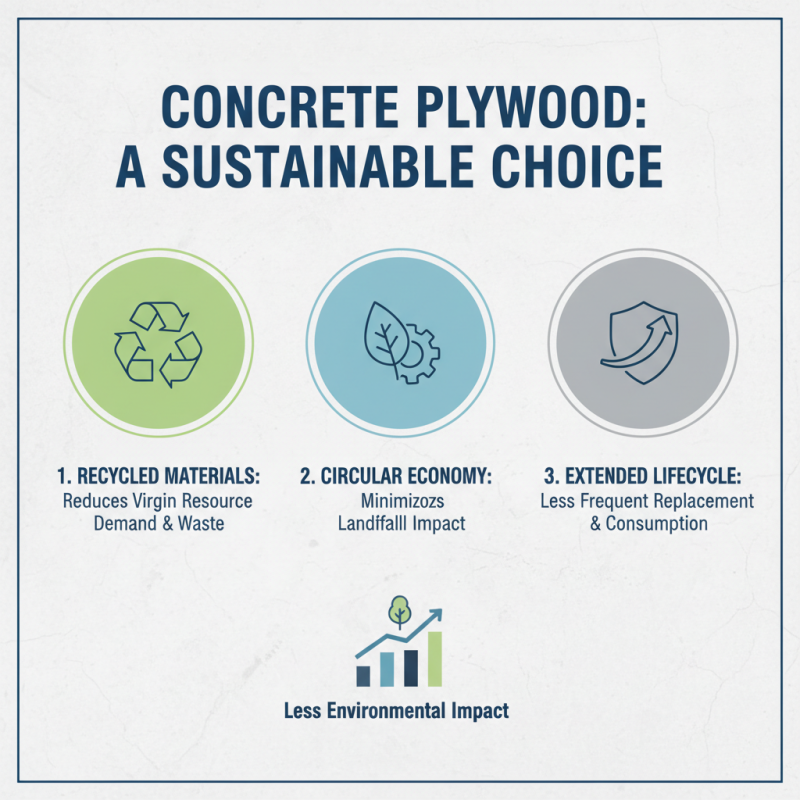

Concrete plywood presents a sustainable alternative in construction projects, significantly contributing to environmental conservation. One of the primary sustainability factors of concrete plywood is its production process, which often incorporates recycled materials. This practice reduces the demand for virgin resources and helps minimize waste, promoting a circular economy. Furthermore, concrete plywood's durability means it typically has a longer lifecycle than traditional building materials, leading to less frequent replacements and reduced resource consumption over time.

Additionally, concrete plywood offers excellent insulating properties, which can enhance energy efficiency in buildings. By improving thermal performance, structures using this material may require less energy for heating and cooling, ultimately leading to lower greenhouse gas emissions. Utilizing concrete plywood aligns with green building practices, fostering an ecosystem where construction contributes positively to environmental goals. Through its inherent characteristics and resource-efficient production methods, concrete plywood emerges as a pivotal material in advancing sustainable construction practices.